Suppose I asked the question what are your Logistics Challenges? To a room full of operational people like project managers and engineers. I am sure I could get hours of examples of logistics challenges and how they mess up their ability to do their job.

I could ask anyone from almost every level in a business. Even friends and families and still get an answer dominated by the challenges or, to put it another way, the negative impact of challenges.

I don’t blame people, especially in the current world climate where we see substantial rate increases across the board, but with a never-ending list of delays and issues. However, the perception is that companies cannot rely on Logistics to deliver.

For the people that know me, I do have a favourite saying:

“Perception is reality”

My second favourite saying, especially in my days as a Logistics Manager, was

“I am always wrong, just some days I am less wrong”

Logistics success has always been gauged on not what it does well but on what it does wrong.

Bit of Data

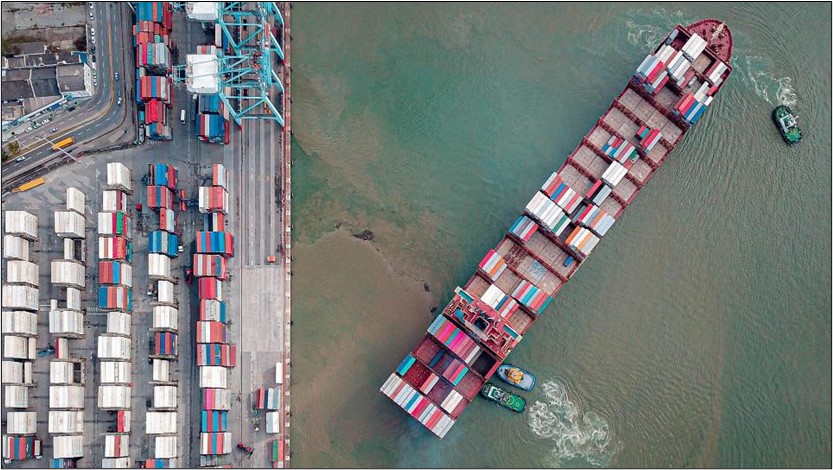

The volume of freight worldwide is staggering. For Seafreight alone in 2020, 815.6 million TEUs were shipped.

Although a slight decline in previous years, it was during the early and more restrictive stages of Covid is no less impressive. If the majority of the volume shipped was delivered without a challenge then is it fair to judge the whole of Logistics based on perception?

It is one of the few industries where it is not noticed when it’s done well. Amazon delivers the package when promised. The inventory turns up on time. The container moves to the port as expected.

Nobody notices the delivery of these milestones or recognises the work needed to achieve them.

When the amazon package is delayed by one day or even one hour, the inventory turns up the day after, or the container arrives at the port too late. Then the bells and alarms go off, and fingers get pointed.

If not Logistics, then who?

I have been working in and around logistics most of my adult life. Therefore, I am not blinkered or will even try to claim that Logistics is perfect.

Ultimately, we are an industry that hasn’t developed in the last 30 years. We are still reliant on the manual execution of the operations. There are gaps in how data is captured and tracked and how it can be used across the business.

Limited competition

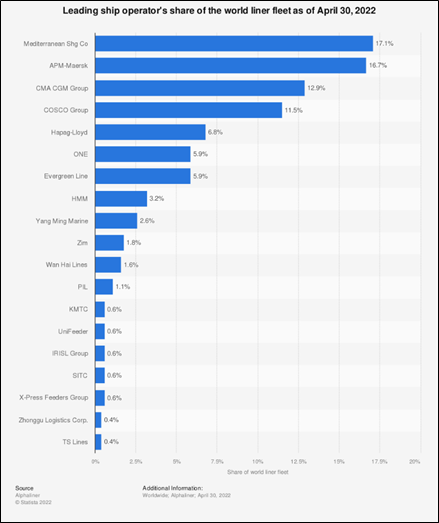

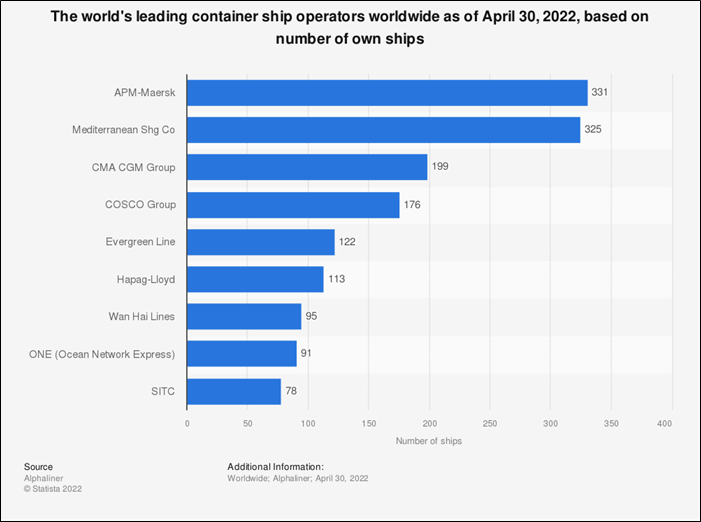

As of 2022, there are three carriers that ship nearly 50% of the freight. If you expand that to the top 5, then almost 65%. The top 7 then nearly 75%. You get the picture.

Market Share versus vessels operated.

I am not sure many industries have as few options on a global scale. And yes, before anyone starts, I know that there are many more carriers in the world. They are not the ones carrying your volume, though.

The top 10 carriers worldwide are also cooperating under Ocean Alliances, an agreement to share vessel routes and co-load.

Airlines have been doing this for many years, and in principle, it allows for cost savings and efficiencies. However, it could be suggested that this may not be the case as the average EBIT for the carriers has increased to around 57%

This is not something that you or I can fix. The cost of entry into the shipping world is vast, and the investment needed is constant. Only the government level could provide a more even playing field.

To add some balance, before Covid, the carriers were in a darker place regarding profit and earnings. People expected low prices, and the carriers needed to survive. Does anyone remember Hanjin, a global provider that went bankrupt?

Cheap Freight

Isn’t this a slight contradiction to Limited competition? Yes, and for a good reason. For the last 10 – 15 years, the ocean market has been in a price competition with each as the average EBIT was closer to 5%. Reducing the competition and increasing the domination of the leaders.

Most leading trade routes had over capacity, so competition was fierce to fill their vessels. I remember when shipping from Europe to China was free so that they could get their containers back to where needed.

These good times for shippers created an operational challenge. It wasn’t necessary to look to long term. We could find a vessel for next week at a low price. Or we could dangle the volume carrot over the heads of the carriers to lock in cheap long-term rates.

The low price also helped to hide the complexity of what it takes to achieve Logistics. The countless operational activities are underappreciated as the focus was on volume, not value.

End-of-the-line process

Logistics is still considered as the last step activity, e.g. sales sell, then engineers design, project managers – plan and then everyone delivers. At every step, the work gets passed over to the next person in the process. For Logistics, it is generally at the end when the products are ready to go or the project is prepared to start. This puts unbelievable pressure on a very sophisticated piece of the process but overlooks areas where it can add value.

Where is the opportunity

As we move past Covid, I am not sure there is a return to how it used to be. Yet I see this as an opportunity for companies to stop the inertia and realign their operations.

- Logistics is an output of the planning.

- This has always been true, but we need to move the planning window to much earlier in the process.

- Be a part of the bidding process so that more of the expected returns can be realised and delivered

- Engage with the engineers when designing the project scope

- Be part of the strategy to define what the future should look like as Logistics spending is a big piece of the costs

- This has always been true, but we need to move the planning window to much earlier in the process.

- Focus on Cost-effective solutions

- There is more to Logistics than buying cheap freight. This is only a piece of the overall cost of moving cargo worldwide.

- Evolving to costs effective solutions captures savings in the buying process. And protects the savings during the operations.

- There is more to Logistics than buying cheap freight. This is only a piece of the overall cost of moving cargo worldwide.

- Work with your partners, not against

- The carrot and stick approach has been a mainstay for working with partners for many years. It is based on the assumption that you have enough knowledge to know what good and bad looks like

- The service providers are the experts, so the focus is on building trust. Then you can utilise their knowledge to add value to your own.

- The carrot and stick approach has been a mainstay for working with partners for many years. It is based on the assumption that you have enough knowledge to know what good and bad looks like

- Be open to trying new options

- There is more than one way to move cargo. We have grown to default on the shipping lines as part of globalisation.

- As new headwinds change strategic direction, look at the map and see what works best for you.

- There is more than one way to move cargo. We have grown to default on the shipping lines as part of globalisation.

Both within the logistics world and outside has opportunities for growth and change.

Within Logistics, we need to upskill our teams so they can have a better opportunity to modernise how we work—embracing new technology and being leaders in the move to a sustainable world.

But outside Logistics, there is a call to arms to engage earlier and be open to the bigger picture. Focus on the positives of what people do daily and recognise that failure is another chance to do it better.

Logistics, in my mind, is unique in breadth and width and, when engaged with can be a strategic game changer to the business. Yet we all need to evolve to realise potential

Building a sustainable Logistics – Achieving success with sustainability

Whether driven by need, imperative or because it is the right thing to do, Logistics is slowly moving forward on being a sustainable partner. Some

Risk in Logistics delivers Reward: Building success with Incoterms

Take a risk. It’s the only way to keep moving life forward. Probably a reckless thought, especially as we overcome some very challenging times, but

Successful movement from Myanmar;

I have travelled the world doing “Logistics”, experienced some unique places, and met some fantastic people. Yet one of the most memorable was the chance

Building a better Project with Logistics

So, what’s a project? The challenge for logistics is that, at its most basic, every shipment and movement is a project. It has a start

Logistics Challenges: Road to Growth

Suppose I asked the question what are your Logistics Challenges? To a room full of operational people like project managers and engineers. I am sure

Successful Delivery To Burkina Faso

A very exciting project as it was a total door-to-door solution that had everything you needed to keep you on your toes. The expectation was